In 2017, nine critical raw materials were added to the EU’s Critical Raw Materials list. While the 27 materials that have made the list are all “critical”, we have selected another three of the new additions, which stand out as of particular importance to current and future European societal needs.

Bismuth – application in medicines

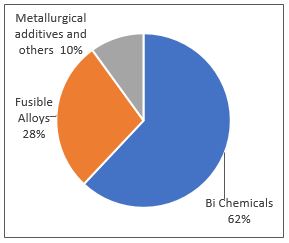

Bismuth is a very brittle metal and shares its chemical properties with arsenic and antimony. Its main physical properties are a low melting point, second lowest thermal conductivity after mercury, and a capacity to expand on freezing. Its main uses are in pharmaceutical and cosmetics products where its non-toxicity is highly valuable. In modern medicine, bismuth compounds are mainly applied clinically for gastrointestinal disorders as anti-ulcer agents. Fusible alloys represent the second most important use. Bismuth is notably used as a replacement for more harmful metals (in particular for lead) in solders. Other uses include metallurgical additives and a number of other industrial applications such as coatings, pigments, and electronics.

Fig. 1. End uses of Bismuth

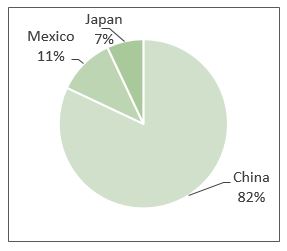

Bismuth occurs naturally in minerals, but is very rarely extracted as a main metal. It is mainly a by-product of lead and tungsten extraction and processing.

Global demand for bismuth is estimated to grow at 4-5% a year. An emerging market could come from the substantial interest in developing new classes of semiconductor, thermoelectric materials and topological insulators, which could lead to the development of emerging semiconductor compounds and alloys that contain bismuth.

Fig. 2. Global Bismuth production, total annual production is around 8,200 tonnes

Helium– inert gas

Everyone is familiar with helium for making balloons float, but there is much more to this colourless, odourless, tasteless, non-toxic, inert, and monatomic gas. Its boiling point is the lowest among all the elements (–269° Celsius). Chemically inert, helium does not form compounds. Helium constitutes about 23% of the mass of the universe and is second in abundance to hydrogen in the cosmos.

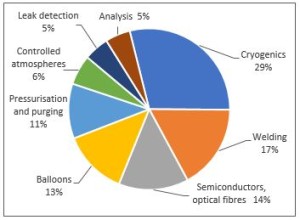

Helium is used as a coolant liquid in cryogenics, as an inert gas atmosphere for welding metals, in the manufacturing of semiconductors and optical fibre cables, in rocket propulsion to pressurize fuel tanks, as a lifting gas, and in high-pressure breathing operations.

Fig. 3. EU end uses of helium, total consumption around 23.8 million m3

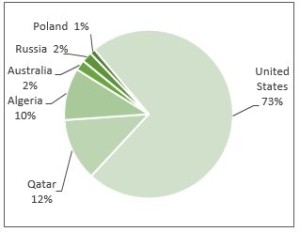

Helium is extracted from natural gas (average content 0.1%-0.5%). It is also recovered during the production of liquefied natural gas (LNG), which consists mainly of liquefied methane. The helium is extracted from the gases that remain after the methane has been liquefied. These tail gases, which have a high helium concentration similar to that of crude helium, are then purified. The end product of the purification process is liquefied helium.

Fig. 4. Global helium production, total annual production is around 167.1 million m3

Vanadium – corrosion protection

Vanadium is a steel-grey, bluish, shimmering and ductile metallic element. It occurs in many minerals and is principally obtained as a by-product from the production of steel. Vanadium resists corrosion due to a protective film of oxide on the surface. Its main application is as an additive in steel (High-strength low-alloy HSLA), and titanium alloys to improve their strength and resistance to corrosion, as well as a catalyst in the chemical industry.

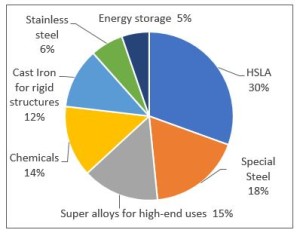

Fig. 5. Global end uses of vanadium

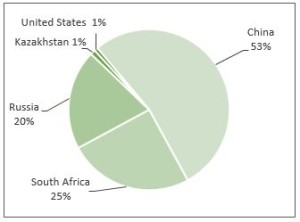

There is no extraction of vanadium in the EU. There are around ten major mine corporations engaged in vanadium extraction and refining, located in the US, Australia, China, Canada, South Africa but also in Austria, Germany and the Czech Republic (for refining). The EU is fully reliant on its imports of vanadium ores and concentrates.

There is some economic activity in the EU specialized in vanadium recycling as well.

Fig. 6. Global vanadium production, total annual production is around 71,000 tonnes

Like many of the critical materials on the EU list, production of these raw materials within EU countries is either severely limited or impossible due to a lack of usable deposits. This creates a high dependency on imports in order to meet Europe’s demands. Substitutions and recycling are limited or not possible, which only exacerbates supply concerns. The materials are placed on the list because securing their supply requires extra attention, cooperation and support as Europe moves forward.