In 2017, nine critical raw materials were added to the EU’s Critical Raw Materials list. While the 27 materials that have made the list are all “critical”, we have selected and will explore three of the new additions, which stand out as of particular importance to current and future European societal needs.

Borates – contributing to energy efficiency

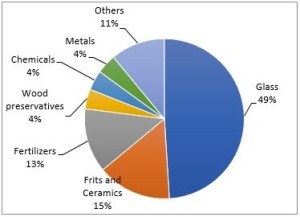

Borates are used in the production of soda glass, Pyrex, fiberglass and heat-resistant glass as well as in detergents, ceramic tiles and glazes, wood treatments, pest control products, flame retardants, home insulation, safety components in cars (such as airbags and brake fluids), healthcare and as a micronutrient in agriculture.

Fig. 1. EU end uses of borates, average figures for 2010-2014, total consumption of around 285 000 tonnes

The element boron does not naturally occur in its elemental form, but it is found in rocks, soil and water. It is acquired commercially through borates, which are naturally-occurring minerals that contain high levels of boron. Borates have metabolising, bleaching, buffering, dispersing and vitrifying properties and are important in the health of both humans and plants. They are completely safe, posing no health risks to humans or the environment. They are also extremely versatile, playing an essential role in many different industries, many of which cannot use substitutes.

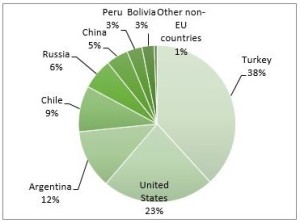

Fig.2. Global Borate production. Total annual production of borates is around 1 million tonnes

The consumption of borates will rise worldwide due to its increasing use in the ceramic, glass and agricultural sectors in South America and Asia. Policy measures on energy efficiency of buildings are expected to drive building standards in Europe and the majority of developing countries, and are likely to increase the demand for borates used in fiberglass building insulation.

Phosphorus rock – supporting food production

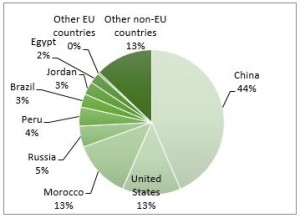

Europe relies on imports for 100% of its phosphorus requirements, as there is no domestic production in the EU.

Phosphorus rock, which is a general term for any rock with a high phosphorus content, is the main source of phosphorus from the earth’s crust. It plays a significant role in bio-based economic processes in the global economy, because it is vital to all life on the planet.

Fig. 3. Global production of phosphate rock (average for 2010–2014) was about 217 million tonnes

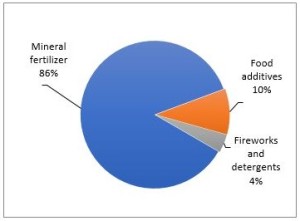

Phosphorus rock is the source of many fertilisers, animal feed, food and other lesser applications such as in water treatment, fire safety, electronics, lubricants and medical applications. Much of the world is experiencing an increasing demand for phosphate for agriculture, because of the growing world population and increasing meat and dairy consumption.

Fig. 4. Global end use of phosphate rock (Average figures for 2010-2014). EU consumption is 7.3 million tonnes

Like many other fertilisers, the use of phosphates has environmental impacts that need to be managed. However, with the growing world population, increasing food production is a priority.

Tantalum – Electronics and space applications

Tantalum (Ta) is a silvery-grey hard transition metal that is very dense and is extremely resistant to corrosion. It is quite rare and does not occur as a free metal in nature. It is often associated in ore bodies with niobium, tin and/ or lithium.

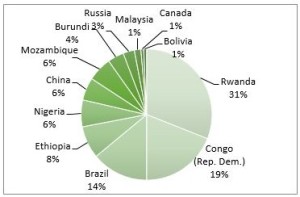

Fig.5. Global production of Ta concentrates (average 2010–2014)

Total production around 1,800 tonnes

The EU relies on imports for 100% of its tantalum ores and concentrates requirements.. Substitutions and recycling are limited or not possible, which only exacerbates supply concerns.

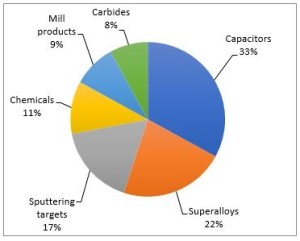

Tantalum is used in a variety of alloys, creating added strength, ductility and higher melting points. These superalloys are perfect for spacecraft and other aerospace applications that must tolerate high temperatures. Tantalum is also used in sputtering targets (e.g. storage media, inkjet printer heads), cutting tools, mill products and chemicals.

Fig. 6. Global end use of Tantalum (average figures for 2010-2014)

A critical need for tantalum is for capacitors for electronic devices. For certain applications, tantalum capacitors are a better suited alternative than their aluminium counterparts. Tantalum capacitors are more reliable, making them the preferred choice for medical electronics and space equipment. This reliability combined with the fact that they are significantly smaller makes them ideal for mass market electronic devices such as laptops and mobile phones.